2K Dosing System 2 Component Ab Mixing Dispensing Machine Thermally Conductive Epoxy Silicone Compound Potting Machine

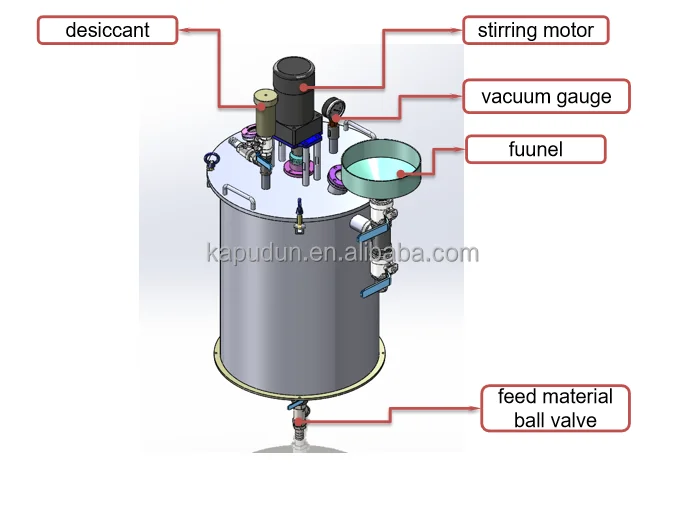

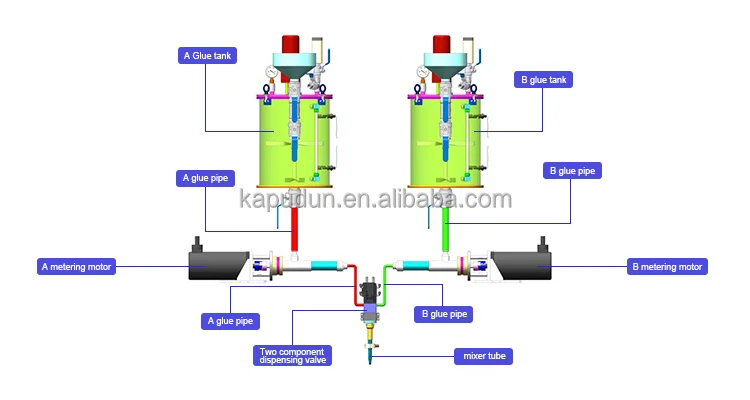

The machine will have two tanks for keeping Liquid A & B separately.

There are two sets of metering pumps inside the machine, draining out liquids individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data .Automatic glue mixing machine is mainly used for a two-component glue( Epoxy/ Silicone/PU,etc adhesive), automatic metering and mixing the ratio by two sets of high precision pumps, supply to a fully mixing design and then dispensing , dosing , dispensing the aimed products .

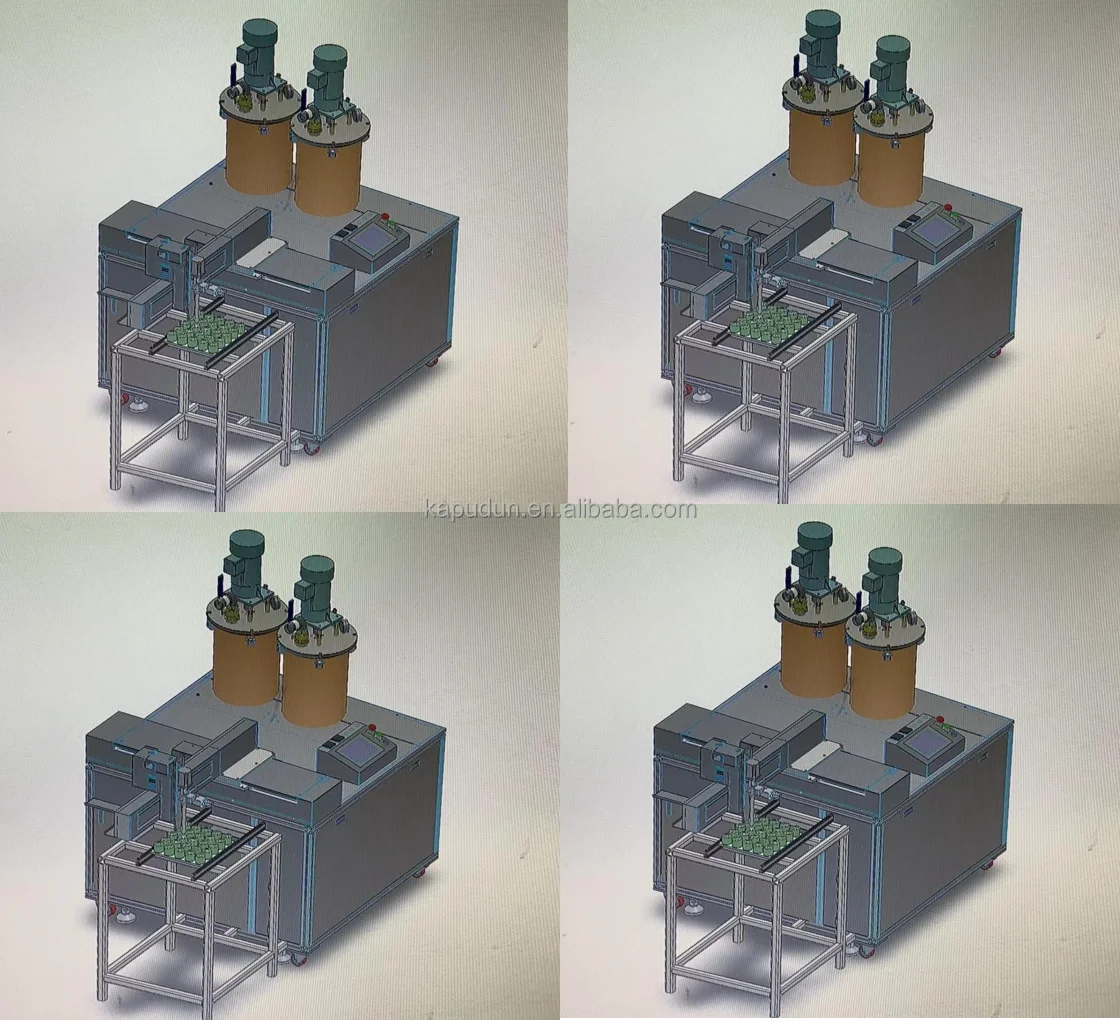

* Machine picture :

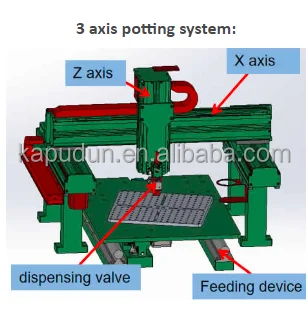

* Working principle :

* Applications :

Industry: capacitor, power supply, transformer, ignition coil, reverse sensor, circuit board, electronic ballast,PCB boards, water pumps ,power supply and other electronic products and product or parts where want encapsulation &potting demanded.

Two components glue, AB glue, AB part glue, silicone, epoxy resin, polyurethane;

All kinds of two-component mixed glues with required ratio, such as epoxy resin AB glue, polyurethane, silica gel, PU glue,flocking glue, paint, etc.

Automatic 2 component 2 part AB Silicone Epoxy Resin Urethane Resin Meter Mix Dispensing Machine Robot Price Description:

silicone dispensing system fluid dispensing equipment automated liquid dispensing equipment Liquid Dispenser Machine For AB Potting Compound Glue Dispensing Machine For Epoxy Resin And Hardener Automated Liquid Dispensing System Adhesive Dispensing Dosing Machine fluid dispensing systems Epoxy dispenser 2 part epoxy dispensing equipment AB dosing dispensing robot adhesive dispensing systems for electrical potting compound epoxy dispensing machine liquid dispensing system for resin and hardener meter mix dispense equipment works for potting compound for electronics automatic glue dispensing machine in line static mixer two part epoxy resin hardener dispensing machine adhesive dispensing robot for high temperature potting compound automated adhesive dispensing system for adhesives and sealants epoxy pump dispenser metered liquid dispenser bi-component epoxy mixing machine resin dispenser AB component liquid dispensing equipment automated glue dispenser epoxy and hardener for potting epoxy for electronics industrial liquid dispenser automated epoxy dispenser 2K Dosing dispensing equipment static and dynamic mixing metered pump dispenser for epoxy PU silicones for electronics glue dispensing system for pcb potting resin dispensing systems clear potting compound resin mixing machine epoxy resin dispenser resins pump dispenser for urethane potting compound epoxy dispensing systems for potting resin for electronics adhesive dispenser machine electrical potting epoxy dispensing system silicone dispensing system fluid dispensing equipment automated liquid dispensing equipment 2 part dispensing systems potting dispenser machine Automatic silicone dispenser with cleaning heating vacuuming functions epoxy mixing equipment fluid dispensing machine epoxy potting machine with gear metering pump system glue dispensing epoxy resin dispensing machines for polyurethane potting compound for electronics meter mix dispense automated fluid dispensing system ab glue dispensing machine epoxy dispensing equipment with precision metering pump dispensing equipment manufacturers polyurethane dispensing machine sealant dispensing machine epoxy resin with pump dispenser vacuum chamber system ab meter mix dispensing machine glue dispenser robot for epoxy resin materials resin dispenser machine with precision gear pump epoxy encapsulation potting dispensing machine sealant dispensing equipment automated robot dispenser vacuum potting machine with high precision pump metering adhesive application equipment with air bubbles degas function epoxy resin encapsulation machine with heating to avoid humidity epoxy resin potting dispensing machine for led encapsulation hardener resin epoxy machine glue dispenser machine price industrial sealants and adhesives device with competitive price manual glue dispenser for all kinds of adhesives meter mix system with vary mixing ratio for resin and hardener vacuum encapsulation machine vacuum potting system

Product Overview

Glue dispensing machine, also known as AB double-liquid glue dispensing machine, is an automated machine that controls fluids and drips, coats, and seals liquids on the surface or inside of products to achieve sealing, fixing, waterproofing, etc. Generally, two-component glue is used. It is mainly used for bonding, pouring, coating, sealing, and filling of glue, oil, and other liquids in product processes. The automated glue dispensing machine can realize the dispensing of irregular shapes such as points, lines, arcs, and circles.

Introduction Applicable liquids adhesive Generally two-component glue used in glue dispensing machines , also known as AB glue, but it is also applicable to single-component glue. Glue A is the main agent and glue B is the curing agent. The most widely used glues on the market are epoxy resin, polyurethane, and silicone. The ratio of curing agent to epoxy resin is 1:1, 2:1, 5:1, 4:3, and 10:1

FEATURES AT A GLANCE

1. Vacuum material-feeding system or diaphragm pump feeding system

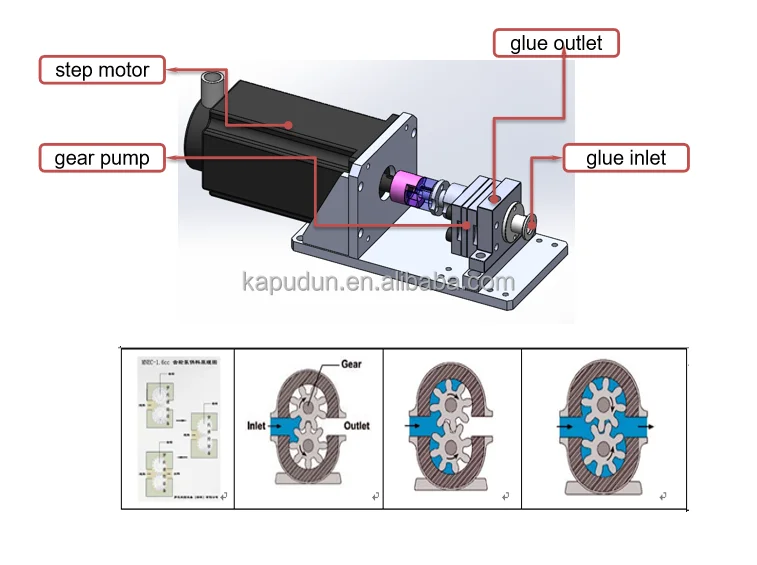

2. High precision pump metering system

3. Dynamic/Static mixing system

4. Three-axis motion system

5. Programming control system

6. Heating function

7. automatic cleaning function.

304stainless steel tank

electrical and pneumatic components

High-quality motion components

Working principle

The machine will have two tanks for keeping Liquid A & B separately.

There are two sets of metering pumps inside the machine, draining out liquids individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data .

PRODUCT SPECIFICATIONS

Models: | KPD-500 Automatic Multifunctional Glue Potting Machine |

Suitable process: | It can be used as a stand-alone machine or with the customer’s original assembly line to achieve on-line gluing. |

Proportion of glue: | 10:1 – 1:1 |

hybrid approach: | Dynamic stirring mixing/static |

Machine Stroke: | 500x500x100mm |

speed | X、Y axle 400mm/s |

accurate | ±0.05mm |

Programme stock: | 999 |

programmer | Teach-In Programming |

metrological: | High precision metering pumps |

control method: | PLC+touchscreens |

input method: | Touch screen + buttons + IO |

Appearance Material: | Industrial square tube welding + 6061 alloy + cold rolled plate |

Drum size: | A barrel 30L, B barrel 10L (can be customised) |

External Dimensions: | 1100×1350 X1600mm |

Gum flow rate: | 1–80g/5sec (customised large glue volume available) |

trajectory: | Punching points, walking straight lines, curves, drawing circles, arcs, squares, and other irregular shapes. |

Supply Voltage: | AC220V/50HZ |

Application areas Glue dispensing machines are commonly used for LED display screen glue dispensing, LED energy-saving lamp glue dispensing, LED power supply glue dispensing, LED light strip glue dispensing, computer power supply glue dispensing, relay module glue dispensing, sensor glue dispensing, PCB board glue dispensing, solar panel glue dispensing, coil inductor glue dispensing, soft light strip glue dispensing, point light source glue dispensing, LED surface mount screen glue dispensing, etc.

General classification (1) Simple glue dispensing machine, the composition is relatively simple, two material barrels, one cylinder, the glue is pressed out and mixed by gas pressure, the general ratio is about 1:1, mainly used in some low-end products that do not have too strict requirements on glue dispensing process.(We do not offer it) (2) Semi-automatic glue dispensing machine, this type of glue dispensing machine can realize automatic proportioning of various proportions of glue, but this type of glue dispensing machine does not have a motion control platform, and directly injects glue into the product to be dispensed. It is generally suitable for LED energy-saving lamps and power supplies. (3) Automatic glue dispenser. This type of glue dispenser can not only automatically mix glue in multiple proportions, but also meet the requirements of 1:1-10:1 mixing glue dispenser operation. It also has a motion control platform and can move in a straight line or three-dimensional path. The three-dimensional path is more advanced and is generally controlled by a computer and is suitable for various types of products. Automatic glue dispensers are used for large-area glue dispensers and products that require relatively uniform glue dispensers. Among them, LED module glue dispensers are the most common. (4) Online glue dispensers. This type of glue dispenser has the highest degree of automation and can automatically dispense glue on the assembly line. It has been successfully used in battery cover and bulb lamp assembly line glue dispensers.

Operation type classification There are two main control operation modes for domestic glue dispensers, namely touch screen control and computer control: 1. Touch screen control Embedded touch screen controls the proportion of glue mixing, glue volume and glue output speed; 2. Computer control The computer control panel is used to set the relevant glue dispenser path. It is simple and fast. Through the visual system, it can be clearly seen whether the glue dispenser position is deviated, so that it can be processed as soon as possible to ensure the quality of the glue dispensed product.

Purchasing principles

How to choose and buy Before buying a glue dispensing machine, you first need to clarify two things: 1. Basic characteristics of the glue used a) What kind of glue is it, single component or two-component (AB glue), b) If it is two-component, what is the weight ratio of AB glue, c) The viscosity and density of the glue, d) How long does it take for the glue to start curing and the time for complete curing, e) How to package the glue, 2. Requirements for the glue dispensing process a) What are the requirements for glue dispensing accuracy, and how much glue is used for each product, b) Glue is used for potting, pasting, insulation, moisture-proof, and dripping, c) How to achieve the glue dispensing operation,

Selection principles 1. Glue: Ordinary glue uses a single-component glue dispensing machine, AB glue uses a two-liquid glue dispensing machine, PU glue uses a PU glue dispensing machine, and UV glue uses a specific syringe for dispensing. 2. Glue potting process: semi-automatic glue filling machines (such as foot control) are used for ordinary glue filling, and desktop, three-axis, circle drawing and other glue dipensing machines with automatic functions are used for precise positioning and marking. The automatic function of the glue dispensing machine is actually an auxiliary function. The glue dispensing machine plays a more important role in controlling the glue, and other functions can be achieved with the help of automated manipulators. 3. Work efficiency and environment: There are few products, and efficiency is not pursued. Manual glue guns are used; glue guns are used for outdoor work. If the amount of glue output is required to be precisely controlled, machines are used. If automated glue dispensing is required, machines with automated functions are used. 4. Cost: There are many glue filling solutions. Not all glue potting/dispesning requires the use of machines, and not all automated glue dispensing must be attached to glue filling machines. From a cost perspective, if a certain glue requires a machine that is too expensive, you can consider replacing the glue. If the price of the glue dispensing machine with automation is too high, you can consider moving the product instead of the glue dispensing head.

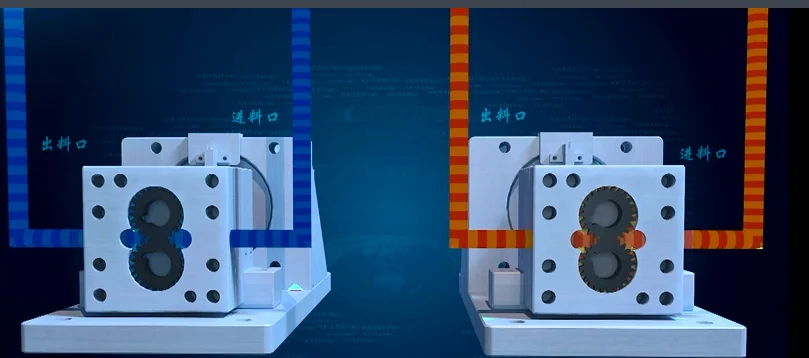

Pump body configuration

1. Gear pump Applied to glue without filler, corrosive, and with viscosity less than 20000CPS Two gears of the same size mesh and rotate with each other in a tightly fitting housing. The interior of the housing is similar to an "8" shape, and the two gears are installed inside. The outer diameter and both sides of the gears fit tightly with the housing. The material from the storage barrel enters the middle of the two gears at the suction port and fills this space. As the teeth rotate, they move along the housing and are finally discharged when the two teeth mesh.

2. Screw pump

Applied to glue with sediment (including some fillers), low corrosiveness and viscosity less than 30000CPS. The screw pump works according to the rotary meshing volumetric principle. The main working parts of the screw pump are the eccentric screw (rotor) and the fixed bushing (stator). Due to the special geometric openings of the two parts, separate sealed chambers are formed. The medium flows evenly from the axial direction. The internal flow rate is low and the volume remains unchanged. The screw pump has stable pressure, so no eddy currents and agitation will be generated. Its biggest feature is its strong adaptability to the medium, stable flow, small pressure pulsation, and high self-priming ability, which cannot be replaced by any other pump type. In terms of later maintenance, the screw pump only needs to replace the stator (screw sleeve), which greatly reduces the cost.

3. Plunger pump

Successful Project

More sucessful project

1.Potting&Dispesing&Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reversesensor, circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts....

Transformer , capacitance , power module , regulating plate ,protection module , generator , pressure package , soli relay ,fault indicator , Sensors , junction box , clutch , wave filter , water meter , boattery cover , rectifier and so on

.2Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling...

3.Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

Automatic 2 component 2 part AB Silicone Epoxy Resin Urethane Resin Meter Mix Dispensing Machine Robot Price was added in Aug 2024

Automatic 2 component 2 part AB Silicone Epoxy Resin Urethane Resin Meter Mix Dispensing Machine Robot Price has been viewed 18 times

评论

发表评论